news

what is the reason for the high power consumption of the motor?

2024-09-20 09:35:21来源:

the reasons for high power consumption of motors may include motor load conditions, motor structure and materials, slip rate, overload operation, inflexible rotation, line losses, etc.

1. motor load condition: if the motor operates under light load for a long time, its efficiency is low and the power factor is also low, resulting in reactive power components occupying the majority and wasting electrical energy. in contrast, motors running at full load have higher efficiency and are more energy-efficient.

2. the structure and materials of the motor itself: the number of poles, the number of poles, the materials (such as enameled wire, silicon steel sheet materials), and the manufacturing process all affect the efficiency and power factor of the motor, which in turn affects the power consumption.

3. slip rate: if the motor slip rate is too large, the load capacity is poor, and the stator current is too high during startup, it can also lead to an increase in power consumption.

4. overload operation: when the motor is overloaded, it will cause an increase in power consumption due to bearing excessive load.

5. non flexible rotation: if the motor itself does not rotate flexibly, it will increase the losses during the energy conversion process, leading to an increase in power consumption.

6. line loss: when the cable connecting the motor to the power supply is too long, the line loss will increase, which will also lead to an increase in power consumption.

in addition, the high power consumption of electric vehicle motors may also be related to factors such as demagnetization of the internal magnetic steel of the motor, aging or damage of the controller, water ingress or demagnetization of the motor, insufficient tire pressure, and brake system failures. therefore, in order to reduce the power consumption of the motor, it is necessary to comprehensively consider the load situation of the motor, optimize the design and materials of the motor, improve the manufacturing process, maintain the good working condition of the motor, and regularly inspect and maintain various components of the motor.

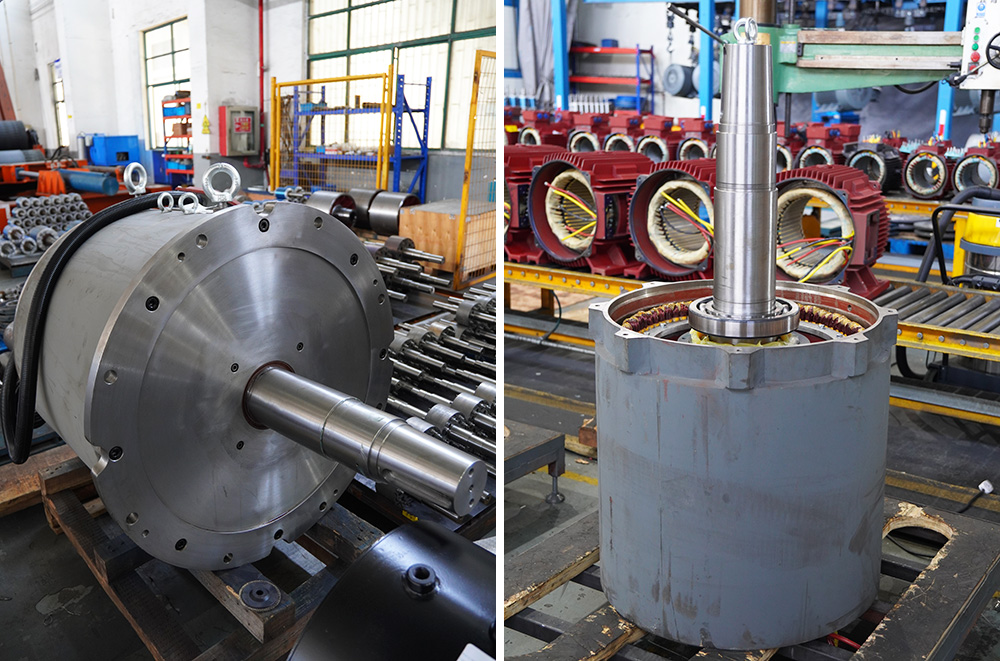

hengda electric has always been dedicated to the research and development, production, and service of various types of motors. with advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.