news

what are the causes of short circuit faults in motor windings?

2024-11-21 14:54:39来源:

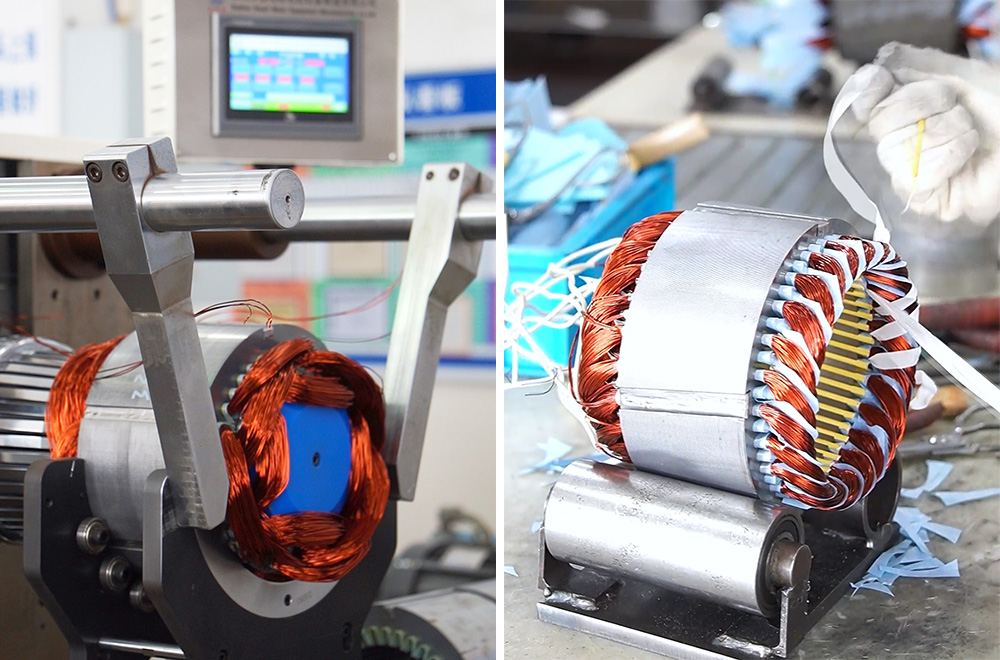

the motor winding is one of the core components of the motor, which is made up of wires wound in a specific way to form the electromagnetic part of the motor. the main function of the winding is to generate a magnetic field and induced electromotive force, thereby achieving energy conversion and transmission in the motor. in motors, windings are usually divided into stator windings and rotor windings, which generate a magnetic field through the action of current to drive the motor to operate. the design and manufacturing quality of windings directly affect the performance, efficiency, and reliability of motors. but short circuit of motor winding is also a common fault of motors, and its causes are diverse.

the main reasons for short circuit faults in motor windings are as follows:

1. manufacturing defects:

·raw material quality issues, such as poor insulation material quality.

·improper processing techniques may result in defects inside the coil during the manufacturing process.

2. damp:

·during storage or use, if the motor is exposed to humid environments, it can cause a decrease in the insulation performance of the coil, leading to short circuit faults.

·moisture may also undergo chemical reactions with coil materials, further reducing insulation performance.

3. overheating:

·during the operation of the motor, poor heat dissipation or excessive load may cause the coil temperature to be too high.

·high temperatures can cause insulation materials to age, melt, or even burn, leading to short circuit faults.

4. mechanical damage:

·if the motor is subjected to external impact or prolonged mechanical stress during transportation, installation, or use.

·these may cause damage to the insulation material of the coil, leading to short circuit faults.

5. voltage fluctuation:

·during the operation of the motor, if the supply voltage fluctuates too much, it may cause the insulation material of the coil to age or melt.

·overvoltage or lightning strikes may also directly penetrate the insulation layer, causing short circuit faults.

6. iron core malfunction:

·motor iron core faults (such as looseness, deformation, etc.) may lead to uneven magnetic field distribution.

·the uneven distribution of magnetic field may cause electromagnetic force fluctuations in the coil, resulting in insulation damage and ultimately leading to short circuit faults.

7. improper maintenance:

·if the motor is not maintained properly during use, such as regular cleaning and inadequate inspection.

·these may cause adverse environments such as coil dust and oil stains, affecting insulation performance and leading to short circuit faults.

8. operational error:

·careless operation during wire embedding and wiring resulted in the outer insulation of the electromagnetic wire being scraped.

·when welding the lead wire, the temperature is high and it touches the end cap, causing a short circuit.

·the end and interlayer insulation materials are not properly padded or damaged during shaping.

·the winding end is too long and touches the end cover, causing a short circuit.

in summary, the causes of motor winding short circuit faults involve multiple aspects, including manufacturing, use, maintenance, and other aspects. therefore, in the manufacturing, use, and maintenance process of the motor, it should be strictly operated in accordance with relevant standards and specifications to ensure the normal operation of the motor and extend its service life.

hengda electric has always been dedicated to the research and development, production, and service of various types of motors. with advanced technology and equipment, lean manufacturing processes, reliable product quality, and satisfactory after-sales service, the company provides customers with the most suitable motor professional solutions and creates greater social value.